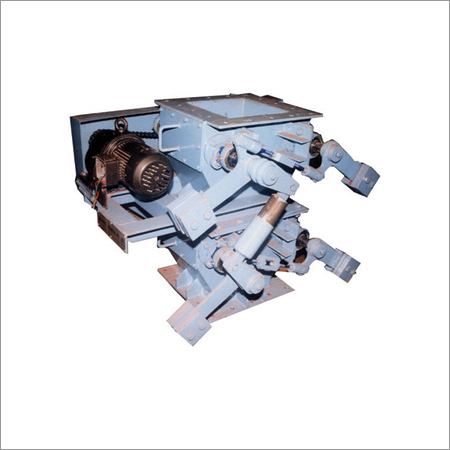

Double Flap Valve

Product Details:

- Height 600 - 2000 Millimeter (mm)

- Usage Industrial

- Size 800 x 1250 mm

- Structure Control

- Type Double Flap Valve

- Click to view more

X

Double Flap Valve Price And Quantity

- 10 Unit

Double Flap Valve Product Specifications

- 600 - 2000 Millimeter (mm)

- Control

- Double Flap Valve

- Industrial

- 800 x 1250 mm

Double Flap Valve Trade Information

- 4 Unit Per Year

- 3-4 Months

- All India

Product Description

Double Flap valves find their application as a substitute of Rotary Airlocks i.e. to allow flow of dust and maintain airlock across the valve. It is particularly suitable for handling highly abrasive and gritty materials along with high vacuum across the valve. Two small hoppers are mounted in-line and with some space between them in an air-tight casing. Two sets of flaps/ cones seat against the discharge openings of the hoppers. The flaps or cones are held on arms that are fulcrummed on two shafts. The shafts are provided with external counter weights to counter balance the weight of flap or cone, the connecting arms and also the material pressure on top. The counter weight is so selected that the flaps / cones close tightly against the seat rings fitted at the discharge end of the hoppers to avoid leakage. The flap/ cone mounting on the connecting arms self aligning type to make the sealing airtight. For cone dump valve, the seats are sometimes provided with additional rubber rings to ensure leakproofness. The drive mechanism of these valves comprises of a geared motor with cam or linkage that alternately turns the two shafts by some degree. This results in partial lowering of the flap pair or cone at two levels alternately. Thus, as the top flap/cone lowers, material above it drops to fill the intermediate chamber. Now the top flap/cone closes and after some pause the bottom flap/cone opens to allow the material to pass out of the valve. The above mechanism ensures that any one flap/cone remains closed at any point of time thereby ensuring airlock across the valve.

Manufacturing Range

- Capacity: Upto 50 TPH

- Size: Upto 800 x 1250

- Height: 600 - 2000

Type:

- Single Cone Double Deck

- Double Flap Double Deck

- Single Flap Double Deck

Operating Mechanism:

- Gravity operated

- Motorised cam operated

- Pneumatically operated

Material of Construction

- Body: IS:2062

- Liner: Sailma/ SS

- Shaft: EN-8 / EN-19/ EN-24

- Cone: Ni-hard/CI

- Flap: IS-2062 with liner

Enter Buying Requirement Details